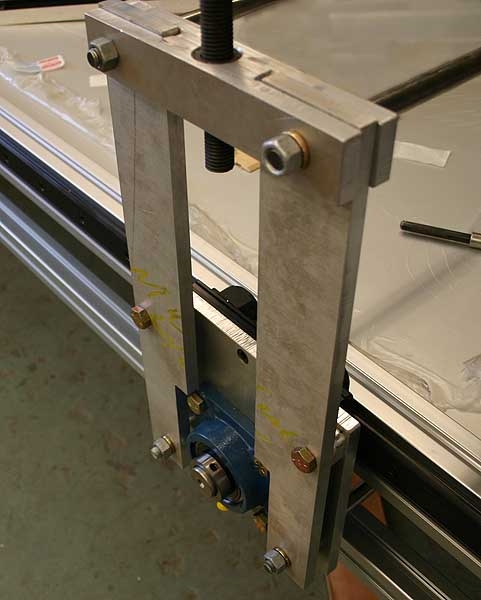

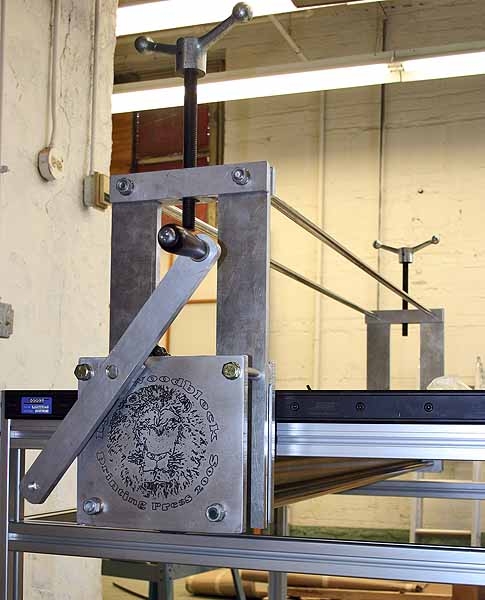

HEY! Last night and this morning I fitted the drive assembly and bearing guides for the top roller — and amazingly, everything fit like a charm — even the keys fit the keyways in the shafts and sprockets! It was especially gratifying when I installed the chain around the two sprockets (what a MESS of grease those chains are!) and the connector link just slipped in precisely — what a perfect fit — the result of all those difficult chain-ring calculations!

But one serious problem has now become apparent — I originally conceived the press with the 1/8 inch bed held (like a drawer-bottom) by the inside slots of the main rails all around. Somehow I managed to under-dimension the press bed by about 3/8 inch, so it is able to slide around quite sloppily, and there’s sufficient deflection side-to-side in the main rails to allow the bed to slip out of its track in the center. I’ve got 1/2 inch between the ends of the rollers and the side rails, though (to make it easier to keep the press bed swept free of wood chips and other debris), so I’ll repair the problem when I attach some lengths of 1/4″ x 2-1/4″ plate to the inside of each top rail and then screw the bed down tight to those, using some flat-head machine screws countersunk into the bed very close to the rails. That should serve to stabilize both bed and side rails without too much work and without interfering with the smooth passage of the rollers across the bed.