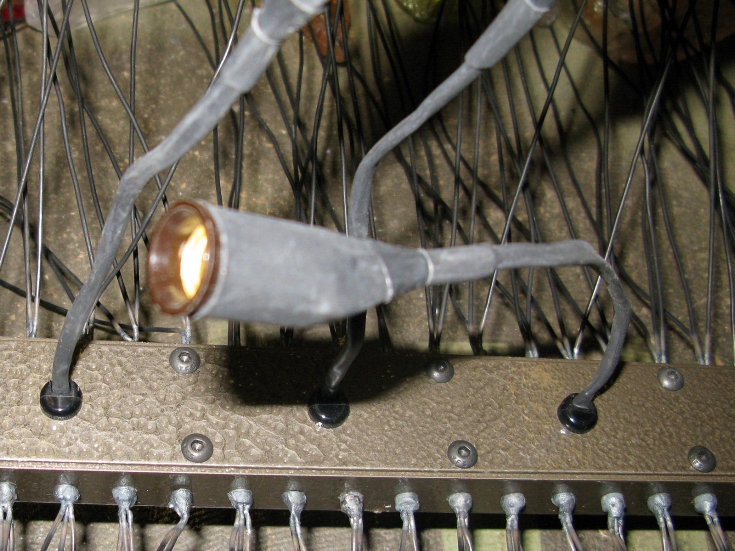

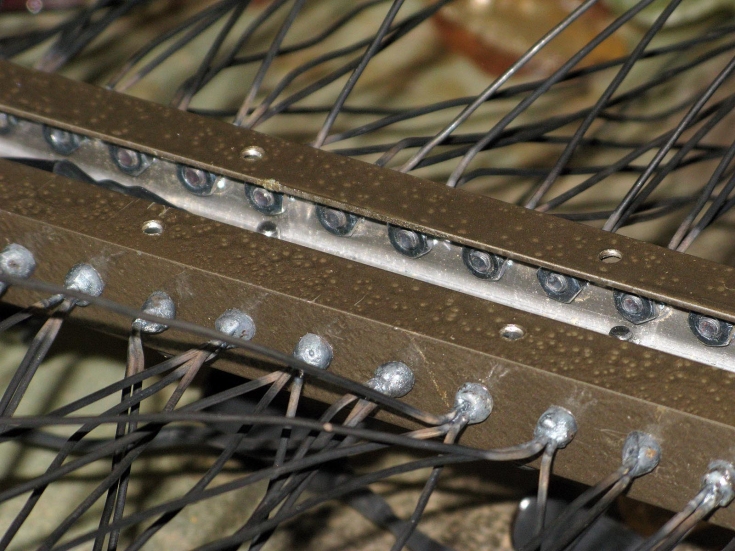

360 individual castings assembled with 24 LED bulbs to make 48 x 18 inch chandelier:

Linda and I spent a pleasant couple of hours sculpting clay leaves at our kitchen table. We used knives and cookie cutters and pencils (this shot was taken after the leaves had been used to produce molds, so they are a bit damaged and cracked). OH! The modeling clay MUST be sulfur-free or the latex won't set up properly (learned the hard way -- YUCKY)!

Linda and I spent a pleasant couple of hours sculpting clay leaves at our kitchen table. We used knives and cookie cutters and pencils (this shot was taken after the leaves had been used to produce molds, so they are a bit damaged and cracked). OH! The modeling clay MUST be sulfur-free or the latex won't set up properly (learned the hard way -- YUCKY)!

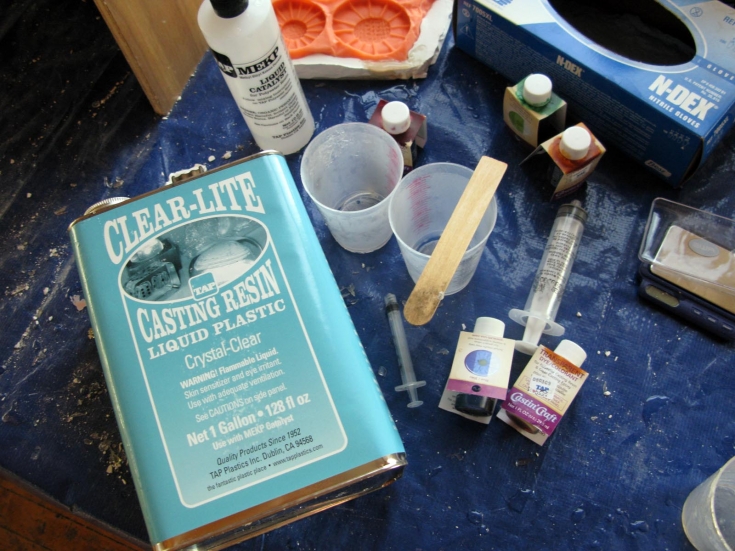

molds in warming box -- polyester resin works best if molds are around 120 degrees F and kept warm during setting up. Polyester does not cure where exposed to air (surface stays tacky). It shrinks during cure, so castings thicker than about 1/8 inch tend to pull away from mold during cure leaving unattractive dull surfaces and, in extreme instances, surface tackiness. Warm molds help a lot! My space heater (low cost) solution worked well, but isn't recommended due to fire hazard!

molds in warming box -- polyester resin works best if molds are around 120 degrees F and kept warm during setting up. Polyester does not cure where exposed to air (surface stays tacky). It shrinks during cure, so castings thicker than about 1/8 inch tend to pull away from mold during cure leaving unattractive dull surfaces and, in extreme instances, surface tackiness. Warm molds help a lot! My space heater (low cost) solution worked well, but isn't recommended due to fire hazard!